Full-Stack Developer & CAD/CAM Programming Expert

I'm a versatile technical professional combining 9+ years of manufacturing experience with advanced software development skills. Currently completing my BS in Computer Science with a focus on Software Development, I specialize in creating custom automation tools that bridge manufacturing operations with modern web technologies.

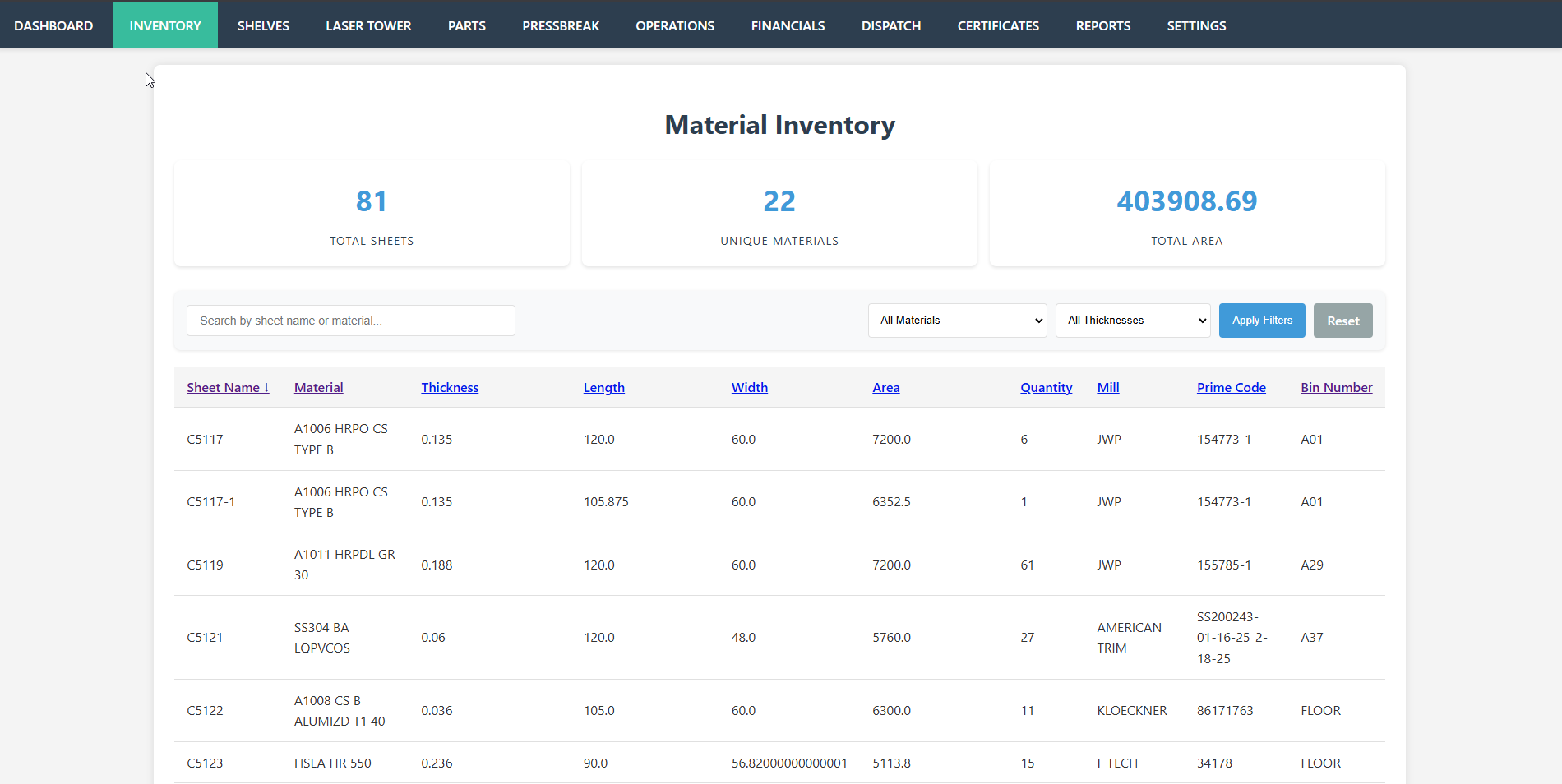

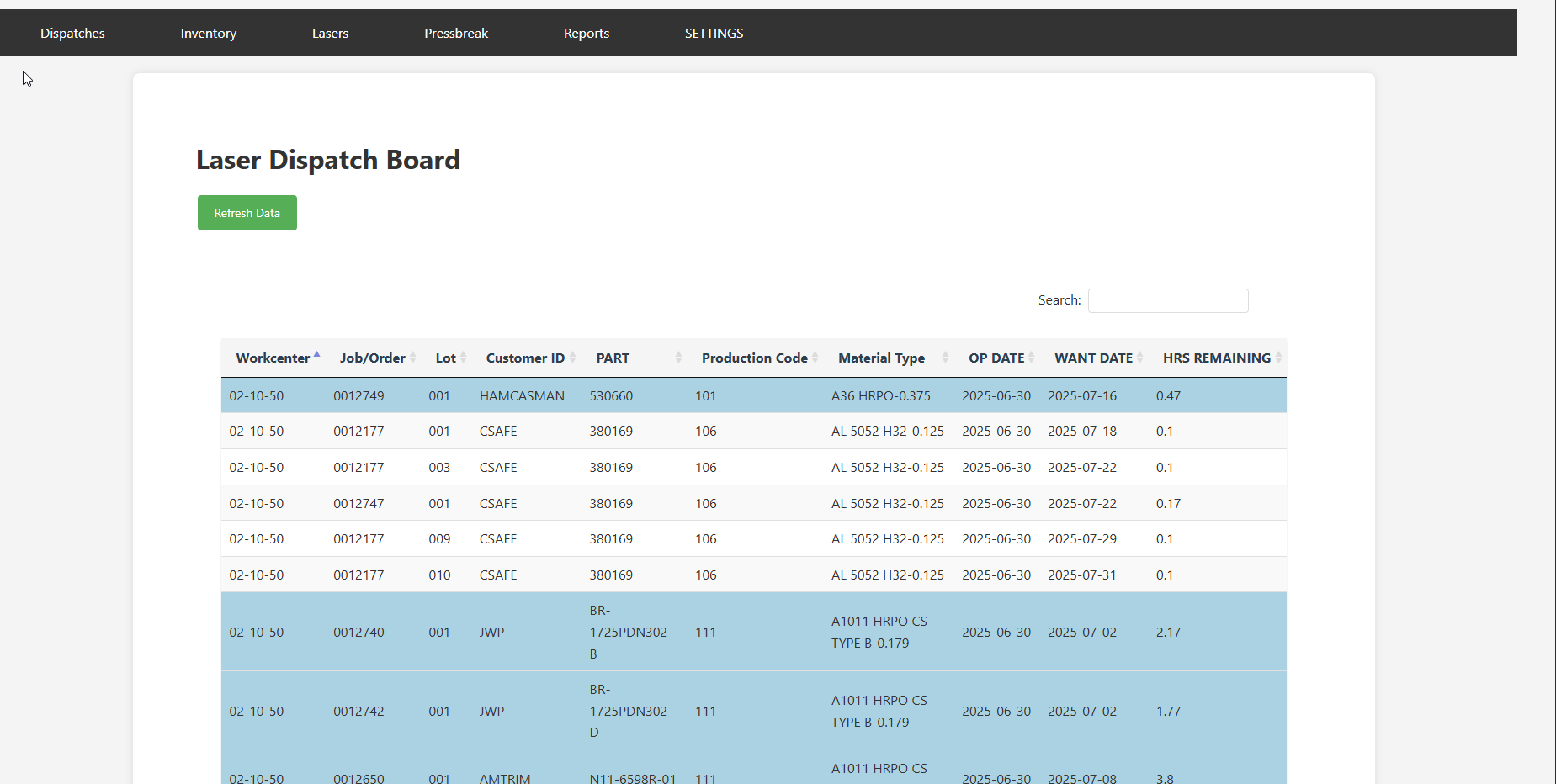

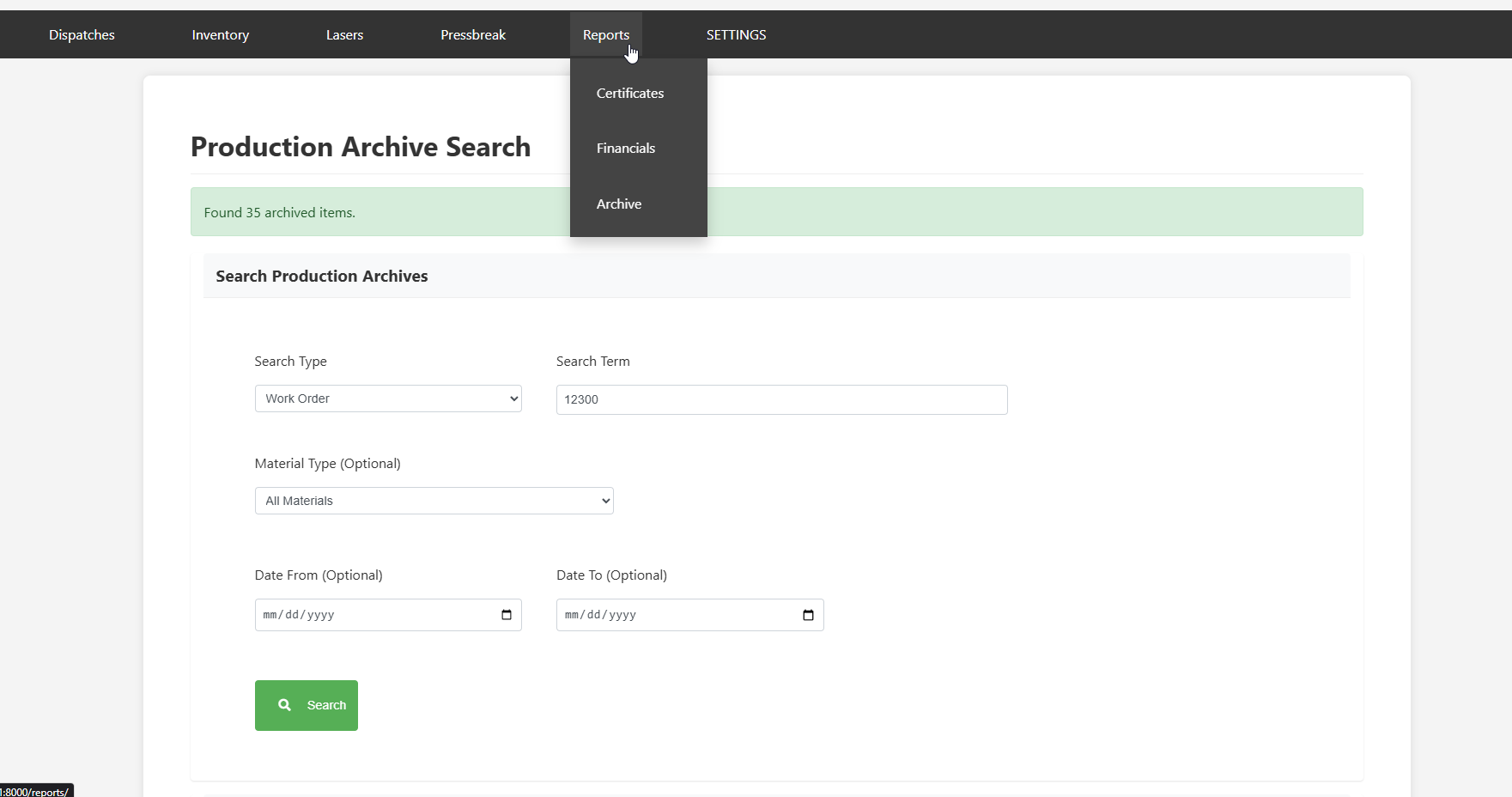

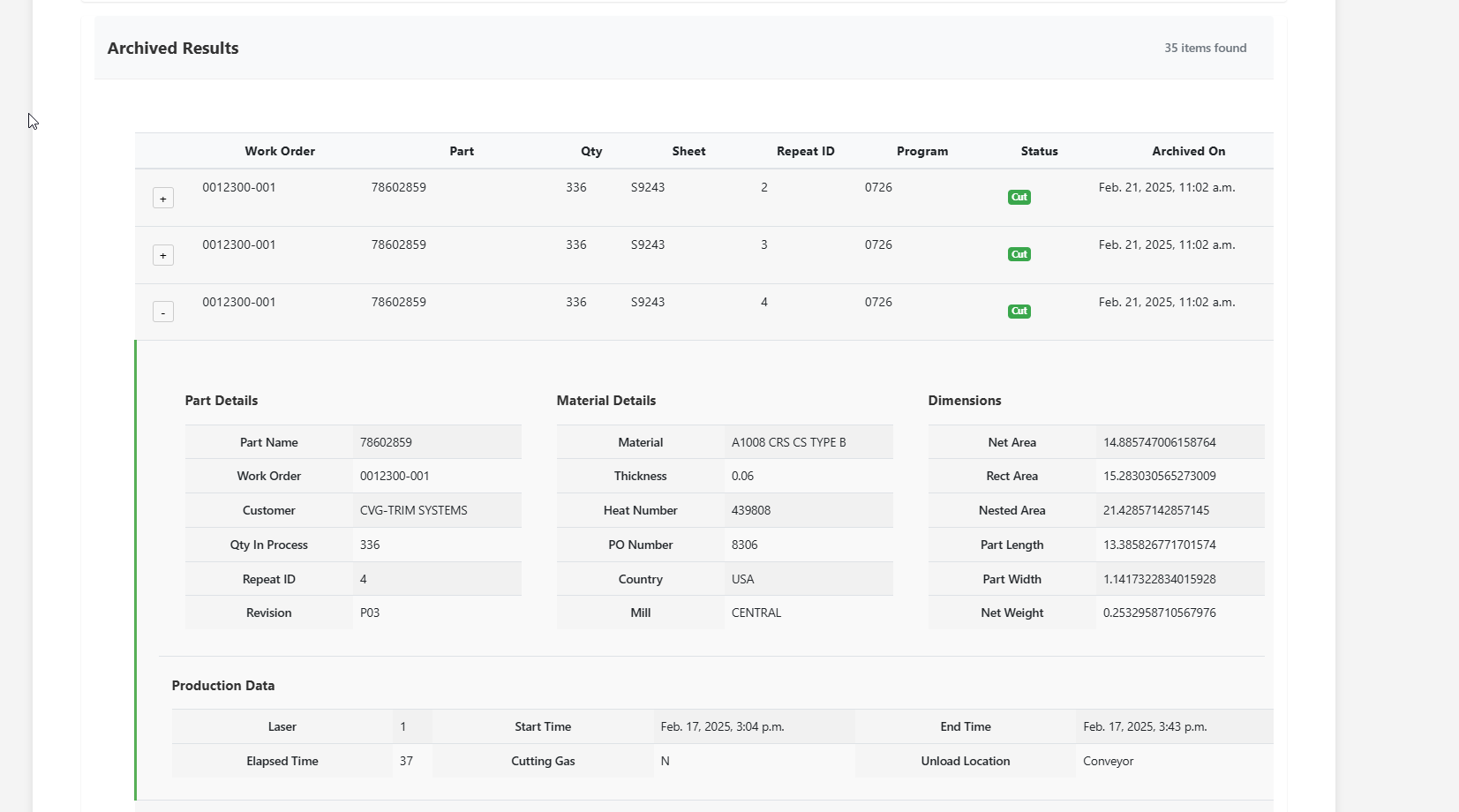

My core expertise centers on Python/Django development, advanced CAD/CAM programming (particularly SigmaNest), and database integration. I've developed the ProgrammingAid system - a comprehensive Django-based manufacturing management platform that integrates multiple databases and provides real-time production tracking with significant performance improvements.